Integration in Sage 200

As Sage 200 is an integrated system you only need enter information once, and it will be used elsewhere in the system. When you enter any data, it is used by the relevant modules.

The Accounting System Manager is used to set up common information and options for all of the Financials modules The Financials modules in Sage 200 are Sales Ledger, Purchase Ledger, Nominal Ledger and Cash Book. and Commercials modules The Commercials modules in Sage 200 are Stock Control, Invoicing, Sales Order Processing, and Purchase Order Processing..

The Manufacturing System Manager is used to set up common information and options for all of the Manufacturing modules, including the Bill of Materials module.

You can choose to update the Nominal Ledger with postings from the other modules immediately on the Nominal Ledger settings Options tab. Alternatively you can hold the postings in a separate file until you select the Update Waiting Postings option.

Each transaction is assigned a Unique Reference Number (URN The unique reference number assigned to a complete transaction to assist in tracing the progress of the transaction through Sage 200. This number is 12 digits long and comprises of: 3 digits for the user number, 2 digits for the source module in which the transaction was created, and a 7 digit sequential reference number.). This helps you to track the posting in the various modules.

To pass information between modules, in most cases you only need to:

- Ensure that the common information is set up in Accounting System Manager. (If you are using the Manufacturing modules, you must set up the Manufacturing System Manager as well.)

- Ensure that your default nominal account structure has been set up in the Nominal Ledger. You should also set up your company's chart of accounts here.

- Ensure that all your customer, supplier and bank account records have been set up in Sales Ledger, Purchase Ledger and Cash Book.

- Select the appropriate Month End tasks in each module to update transactional information.

How the Sage 200 modules integrate

| Module | Integrates with ... |

|---|---|

| Sage 200 Commercials |

Sage 200 Financials:

|

| Sage 200 Project Accounting |

Sage 200 Financials:

Sage 200 Commercials:

|

| Sage 200 Fixed Assets |

Depreciation and disposal of assets make postings to the Nominal Ledger. |

|

Sage 200 Manufacturing, including Bill of Materials |

Sage 200 Financials:

Sage 200 Commercials:

Note - warning

Important! If you are using Bill of Materials with Manufacturing, you will need to follow some guidelines to ensure that the modules integrate correctly. See Integrating BOM and Manufacturing. How Manufacturing integrates with the Accounting modules

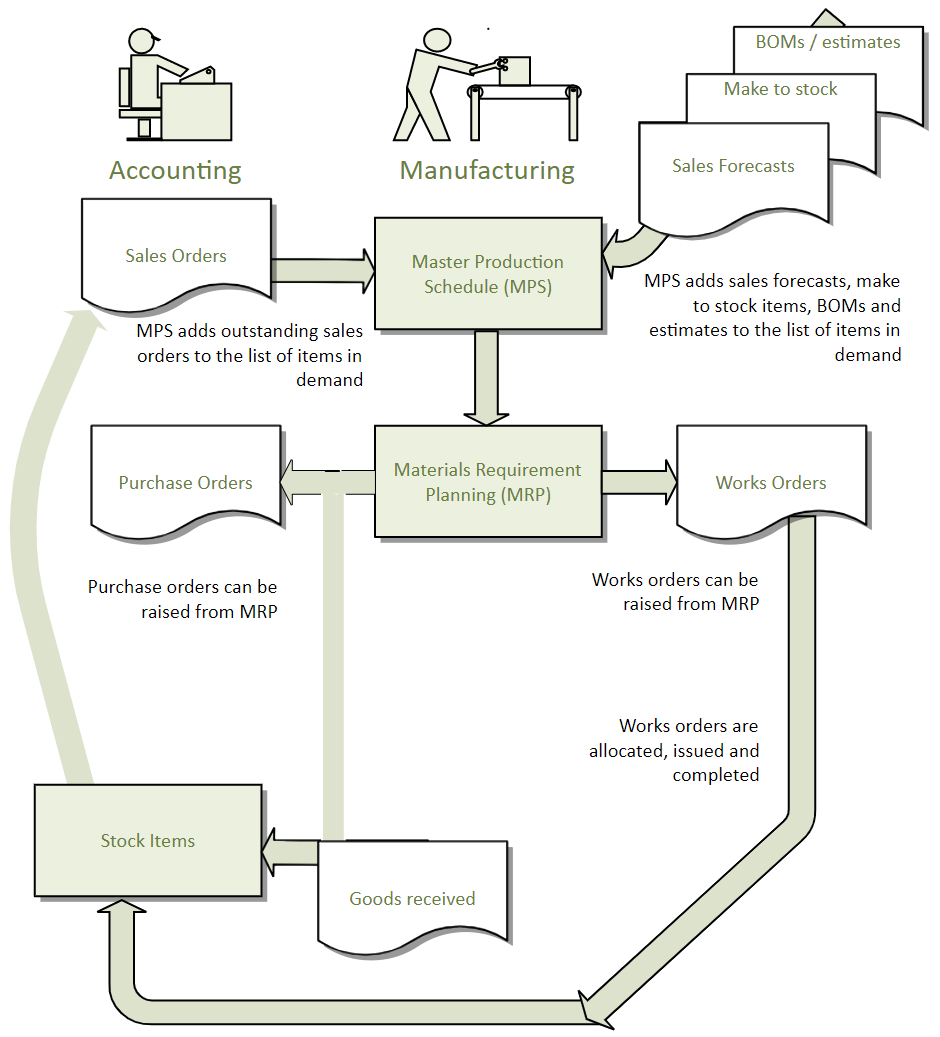

Sage 200 Manufacturing integrates with the Sage 200 Commercials modules. How does information flow through Accounts and Manufacturing modules?

BOM A stock assembly and process costing system, which provides facilities to specify the structure of finished items in terms of sub-assemblies and components.s (bill of materials), estimates Forecast project costs, based on expected costs of labour, machinery and operation times. In Manufacturing, estimates are produced for one-off items or non-repetitive batches., sales forecasts The best estimate of future requirements. This is used as input to the MPS (Master Production Schedule). Forecast orders received should be subtracted from the forecast to leave a residual forecast in the master schedule. Total demands can then be calculated as orders plus residual forecast for each time period., items to make for stock and sales orders are all added to the list of items in demand in the MPS Master Production Schedule (MPS). The planning of production (usually end item production), to satisfy current and forecast sales orders. The sum of MPS items must equal the agreed sales and operations plan for the items over each planning period. Planning periods are normally a month or a four week period. Items planned within MPS are exploded by MRP (Materials Requirements Planning) to produce the material and capacity requirements. module. From the Master Production Schedule (MPS) list, a Material Requirements Planning (MRP) schedule is generated which recommends purchase orders or works orders be created to fulfil the demand. When goods are received they are placed in stock and this allows fulfilment of sales orders. |