Converting an estimate into a BOM

You can convert an estimate into a BOM.

Within estimate settings you can specify whether the primary constraint in BOM calculations following conversion is Machine or Labour.

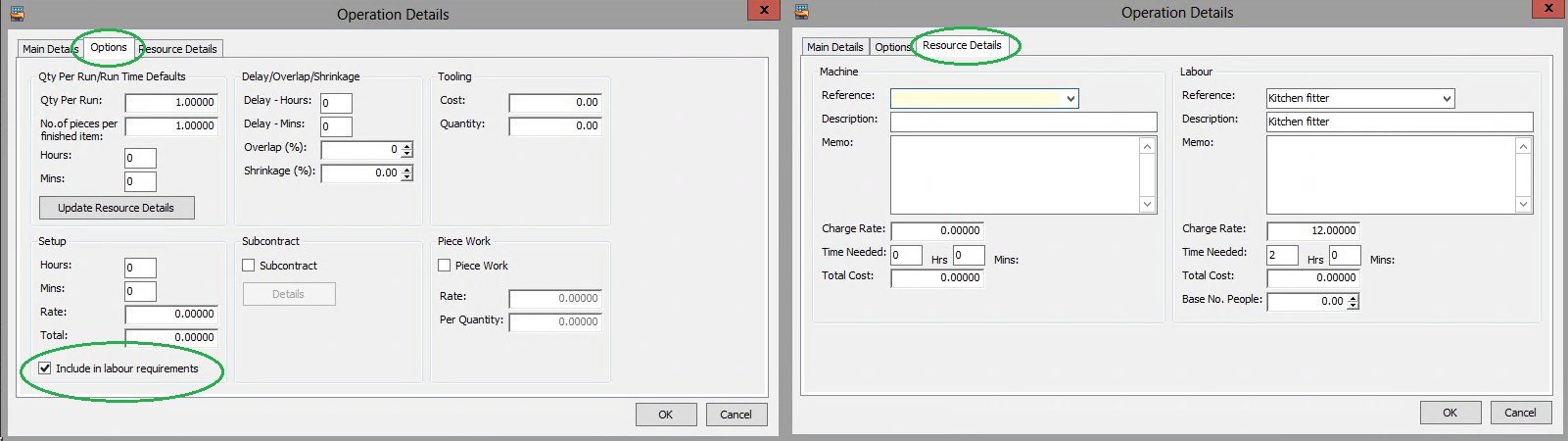

When you enter the estimate stage operation details, you can specify how you want resource costs to be converted. During conversion, only one setup cost can be converted per operation: either a labour or a machine setup cost.

Note: If you need to convert more than one setup cost, you would need to create a separate operation per setup cost.

| Options tab | Resource Details tab | |

|

Select the Include in labour requirements checkbox. |

Select a labour resource. |

|

Clear the Include in labour requirements checkbox. |

Select a machine resource. |

|

|

Select a machine resource and enter a Machine Charge Rate. |

|

|

Select a labour resource and enter a Labour Charge Rate. |

During the conversion process you may be directed to create stock items in the Stock Control module. Any other expenses that have been set up for the estimate are not created on the BOM A stock assembly and process costing system, which provides facilities to specify the structure of finished items in terms of sub-assemblies and components..

After conversion, you can amend the BOM if required.

- Estimating contains no setup time of seconds. Therefore, following conversion, the seconds in the BOM defaults to 0 (zero).

- Following conversion, there is only one setup resource per operation.

You must have:

- Selected Machine or Labour as the primary resource on conversion within Estimating settings.

- Set up the estimate stage operation details to reflect how you want to convert resource setup and running costs. This is set up on the Options and Resource Details tabs of the estimate stage Operation Details window.

To convert an estimate into a BOM

Open: Estimating > Processing > Convert to BOM.

- Select the Estimate No. that you want to convert to a BOM.

-

Click OK.

If you have non-stock items Items which do not have a product record set up in Stock Control. Such items are usually bought for a specific job. on this estimate, the Enter New Stock Item window appears for each item. You must enter a stock code for every non-stock item on the estimate.

When you have entered your product codes, the new BOM appears in the Bill of Materials List and the estimate is cancelled.

The Sage 200 Manufacturing module is now retired, from the Sage 200 Professional 2025 R2 release. We've retained the product help here for customers still using Manufacturing with older versions of Sage 200.

As the module is now retired there is no support from Sage. You can find out more about support in our product lifecycle (opens in a new tab). Please speak to your Sage Business Partner to find out more.