Planning a BOM

A BOM A stock assembly and process costing system, which provides facilities to specify the structure of finished items in terms of sub-assemblies and components. is a list of items needed to build a product.

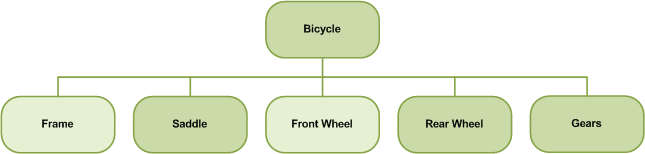

An example of a basic BOM is shown below.

A bicycle is made up of a frame, saddle, two wheels and a set of gears. This type of BOM is known as a single-level BOM. This displays a list of items used to make up the finished product; in this case, the bicycle.

A BOM can also be made up of a number of sub-assemblies. The diagram below shows a multi-level BOM. It displays all components Raw materials used to manufacture finished goods. and sub-assemblies that are directly or indirectly used in the finished product.

Using the example of a bicycle, the wheel and frame can be classed as sub-assemblies. Whilst the company may not sell the frame or wheels separately, they are used to make the final product.

If a sub-assembly When raw materials or components make a part of a finished product. The sub-assembly may be combined with other components or with other sub-assemblies in the manufacture of finished goods. is made for specific use in a BOM, it can be a phantom BOM.

A phantom BOM is a sub-assembly BOM that is not used as a stock component or, if you are using Manufacturing, in raising works orders.

It is created and structured to contain groups of components, like a standard BOM. It is used in printed reports on stock structures. It can also be used to collapse the sub-assemblies to reduce work in progress Work in progress (WIP) is a product's value as it moves through production. This is increased by issuing stock and decreased by completing works orders, returning or scrapping stock. and lead time The number of working days elapsing between placing an order for an item and taking delivery..

It operates as a standard sub-assembly. However, the stock code for the finished item does not appear on a higher level works order.

In Manufacturing, the components and operations of phantoms (and nested phantoms) are added to the top-level works order. These components and operations are given a sequence number of zero.

In some manufacturing systems, phantoms are employed instead of effectivity dates, to use up old stock before introducing replacement parts. If so, the new item is created as a phantom with the old item, the child of the new. Old stock is used up before new stock is ordered. When a phantom has zero stock, it is deleted and the new item is made part of the original BOM.

Phantoms are also known as non-returnable assemblies and blow-throughs.

The stock code for the phantom BOM does not appear at a higher level. For example, the wheel sub-assembly consists of a tyre, rim and spokes. The frame requires alloy tubing and welding equipment. Both require manufacturing, setup and additional labour costs.

When creating a BOM, consider how your finished item is made up and if there is an associated phantom BOM. In addition, consider how you want to apply additional costs to the BOM.