Amend stock allocations

Use Amend Stock Allocations to amend an existing stock allocation or to allocate stock to an order where no allocation has been made.

Batch/serial numbered items may require additional processing depending on your Sage 200 settings. If you have chosen to assign batch/serial numbers to an order prior to retrieving goods from stock, Sage 200 selects the items by batch/serial numbers and you confirm or amend the selected numbers during this activity. The batch/serial numbers are printed on the picking lists if you system is set to do so. Otherwise, Sage 200 allocates the required quantities at given locations, but does not select the batch/serial number. No further action is required during this activity, as in this instance the batch/serial numbers are selected and recorded during despatch after the goods have been retrieved from stock.

Note: You cannot amend an allocation if the order line has been set up to use back-to-back ordering.

Manually amend allocations

Open: Sales Order Processing > Order Processing > Amend Stock Allocations.

-

Use the options to show the allocations you want to amend, then click Display.

-

By order number: Choose a single order or range of order numbers.

-

By order date: Choose a single order date or range of dates.

-

By customer: Choose a single customer.

-

By stock item: Choose a single stock item.

-

By product group: Choose a single product group.

This feature is only available from Sage 200 Professional 2025 R2 version onwards.

-

You can also set the latest confirmed delivery date to be processed in the Ignore items due after box.

Note: If you just want to show all orders, just select Display without entering any other details, then select the orders to amend.

-

-

Select an allocation line from the list, then select Edit Allocation.

-

Select a stock line to process.

Note: If the order line is linked to a purchase order line through the From Supplier Via Stock fulfilment method (back-to-back processing) then you cannot allocate stock to the order line. Stock will be automatically allocated when the goods are recorded as received in Purchase Order Processing.

-

Click Edit Allocation.

-

Enter the new allocation quantity.

-

Batch/serial numbered items:

-

If Sage 200 is set to assign batch/serial numbers to the order prior to despatch, confirm or amend the selected batch/serial numbers.

To amend the selection, click the check box to the left of a number. If you selected a batch item, in the Quantity to Allocate column enter the amount required expressed in the item's stock unit.

Check the selected numbers equal the total quantity then click OK to confirm the selection.

-

You cannot amend a stock allocation here for batch numbered items that are set to A sale may only be from a single batch. To amend the allocation for this item, you must amend the sales order, edit the item line in the order, then select Amend/Batch Serial.

-

-

Click OK to confirm that you have finished allocating the item.

Check which orders require allocation

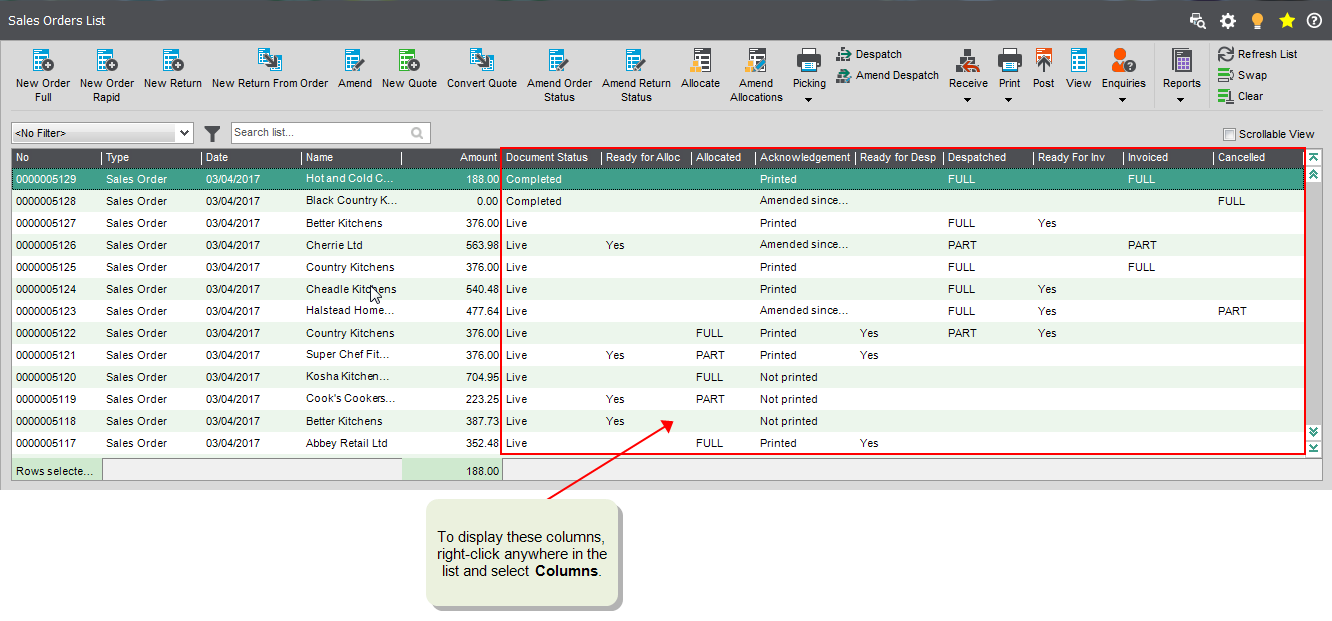

Use the Sales Orders List to see when stock can be allocated to an order, or has been allocated to an order.

Open: Sales Order Processing > Sales Orders List.

- The Ready For Alloc column shows Yes where some items in the order have not yet been allocated.

-

The Allocated column shows:

-

Part: Only some of the items are allocated, but some items still need to be allocated. The items have not yet been despatched.

If you have chosen allocate stock automatically when items are entered on an order (set in SOP Settings), then it is useful to check for Part allocation to see when items were out of stock when the order was entered.

- Full: All items in the order have been allocated. The items have not yet been despatched.

Once an item is partly or fully allocated, it will also be set as ready for despatch. The Allocated status returns to being blank once all the allocated items have been despatched.

-

Open: Sales Order Processing > Sales Orders List.

- Right-click anywhere in the list.

-

Select Columns > Delivery > Ready For Alloc.

Select Columns > Allocated.